-

Main bullet points :-

- Anti-reversion technology for peace of mind.

-

Huge weight saving which contributes to :-

- Snappier performance

- Quicker acceleration

-

Less power required to maintain any given speed due to weight loss resulting in:-

- Less fuel used, significant over time.

- Cheaper over time as they will outlast 3+ standard cast iron systems.

- Adds to resale value to boat especially if still under warranty. No brainer really isn't it ?

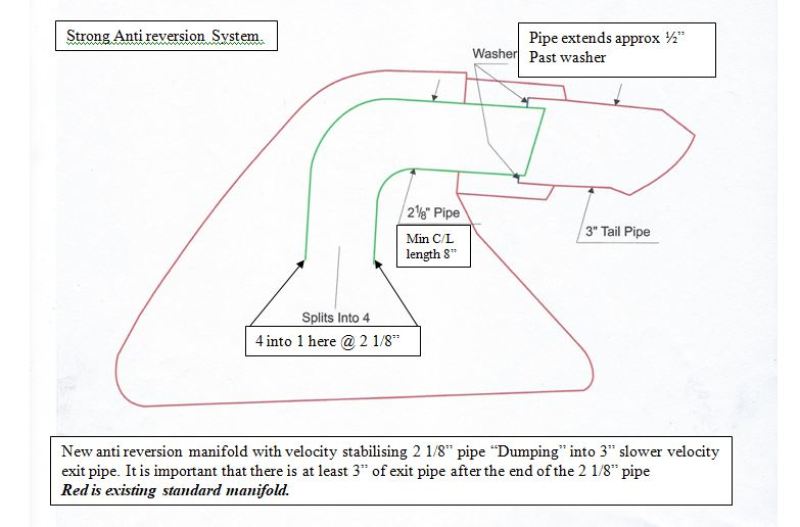

"Swaymar Marine", working closely with "Marine torq" of Australia, have developed what is probably the first dedicated anti-reversion system for marine exhausts. Very few long term boat owners have not experienced water getting back up the exhausts and into the engine and the catastrophic damage that causes. Our anti-reversion system creates a higher velocity gas in the primary pipe so that if "pulsing" should take place in the 3" secondary pipe it is weaker and therefore defeated by the higher velocity gas exiting the smaller primary pipe. See diagram.

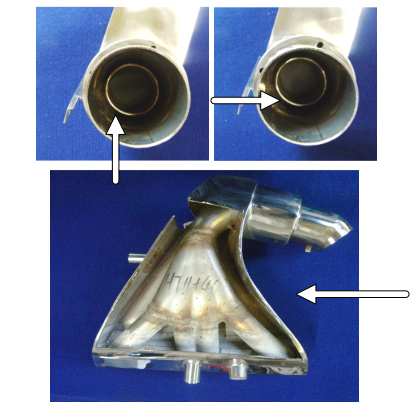

Opposite you will clearly see actual photos of the anti-reversion system as it appears when looking up the 3" secondary expansion exhaust pipe, the cooling water exits from the holes (2x are visible in the top around the outside of the secondary pipe). You will also see a cut away picture of a "cut away" exhaust manifold showing the beautifully flowing collector box joining the 4 individual pipes to the primary pipe leading to the 3" secondary. BUT THIS IS JUST THE FIRST OF MANY ADVANTAGES !.

WEIGHT SAVING :- We all know boats unlike cars are VERY weight sensitive. Worst case scenario. A big block manifold with a 6" spacer weighs in at approx 93lb EACH. The S/S equivalent, pictured right, weighs approx 21lb each. That is a saving of 72lbs each or 144lbs per engine. = 288lbs! in a twin engine boat. The lightest cast iron small block is approx 68lbs EACH S/S equivalent see picture weighs approx 16lbs saving 52lbs each, 104lbs per engine. 208lbs in a twin engine boat. This means, not only will your boat perform better due to an increase in power due to better gas flow design, but also the not insignificant, lose in weight, and also over a period of time you will be using less fuel, as the drop in weight means less energy required to push your boat through the water.

Opposite you will clearly see actual photos of the anti-reversion system as it appears when looking up the 3" secondary expansion exhaust pipe, the cooling water exits from the holes (2x are visible in the top around the outside of the secondary pipe). You will also see a cut away picture of a "cut away" exhaust manifold showing the beautifully flowing collector box joining the 4 individual pipes to the primary pipe leading to the 3" secondary. BUT THIS IS JUST THE FIRST OF MANY ADVANTAGES !.

WEIGHT SAVING :- We all know boats unlike cars are VERY weight sensitive. Worst case scenario. A big block manifold with a 6" spacer weighs in at approx 93lb EACH. The S/S equivalent, pictured right, weighs approx 21lb each. That is a saving of 72lbs each or 144lbs per engine. = 288lbs! in a twin engine boat. The lightest cast iron small block is approx 68lbs EACH S/S equivalent see picture weighs approx 16lbs saving 52lbs each, 104lbs per engine. 208lbs in a twin engine boat. This means, not only will your boat perform better due to an increase in power due to better gas flow design, but also the not insignificant, lose in weight, and also over a period of time you will be using less fuel, as the drop in weight means less energy required to push your boat through the water.

While these exhausts are initially a little more expensive than genuine cast iron ones (and a lot more than copies) they are one piece construction, no joints to start leaking, this is further enhanced by the fact that despite being Stainless Steel, to protect against salt water corrosion they are also, just to be doubly safe, fitted with anodes to protect against the electrolysis that can be encountered on some pontoons, (we all know how quickly even stainless steel propellers can get eaten away.) Because of this they are issued with a 10 year warrantee, Mine have been on 13 years this year, and that is 3 sets of cast iron ones ! which including 3 fitting charges is not cheaper than these. The top picture left shows where the anodes are fitted, the bottom picture left shows the anodes, early type and later type. We carry both types in stock.

One last plus point, is that when you come to sell your boat you will find that these long life, long warranty, reversion safe manifolds definitely add value to your boat, particularly if under 10 years old, they may well be the only part of your boat still under warranty. Particularly when you point out the peace of mind they bring to boating. There are literally hundreds of variations of types and heights of these exhaust systems made, just a couple are shown over, as examples of common and not so common varieties. So the chances of not having Stainless Steel exhausts to fit your boat is very unlikely.

While these exhausts are initially a little more expensive than genuine cast iron ones (and a lot more than copies) they are one piece construction, no joints to start leaking, this is further enhanced by the fact that despite being Stainless Steel, to protect against salt water corrosion they are also, just to be doubly safe, fitted with anodes to protect against the electrolysis that can be encountered on some pontoons, (we all know how quickly even stainless steel propellers can get eaten away.) Because of this they are issued with a 10 year warrantee, Mine have been on 13 years this year, and that is 3 sets of cast iron ones ! which including 3 fitting charges is not cheaper than these. The top picture left shows where the anodes are fitted, the bottom picture left shows the anodes, early type and later type. We carry both types in stock.

One last plus point, is that when you come to sell your boat you will find that these long life, long warranty, reversion safe manifolds definitely add value to your boat, particularly if under 10 years old, they may well be the only part of your boat still under warranty. Particularly when you point out the peace of mind they bring to boating. There are literally hundreds of variations of types and heights of these exhaust systems made, just a couple are shown over, as examples of common and not so common varieties. So the chances of not having Stainless Steel exhausts to fit your boat is very unlikely.